Is It Normal for Window Tint to Look Hazy or Foggy After Installation?

Quick Answer Yes, it is completely normal for window tint to look hazy, foggy, or milky immediately after installation. This cloudiness is caused by trapped moisture between the film and glass during the installation process. The haze will disappear naturally as the tint cures and the moisture evaporates through the porous film material. Curing time typically ranges from 3 to 5 days in warm, sunny weather to 2 to 4 weeks in cool or humid conditions. Small water bubbles may also appear during this period and will resolve on their own. The key is patience: avoid rolling down windows for at least 48 hours and don’t clean the tint for 60 days to allow proper adhesive bonding. You just left the shop with freshly tinted windows, excited about the sleek new look and promised UV protection. But when you inspect your vehicle, the windows look cloudy, hazy, or even milky instead of crystal clear. Naturally, concern sets in. Did the installer mess up? Is something wrong with the film? The short answer brings relief: this hazy appearance is not only normal but expected after professional window tinting installation. Understanding why this happens, how long it lasts, and what to expect during the curing process helps you avoid unnecessary worry and ensures your tint performs optimally for years. This guide explains the science behind post-installation haziness, distinguishes normal curing from actual problems, and provides the care instructions that protect your investment. Understanding the Window Tint Installation Process To understand why haziness occurs, you need to know how window tint is applied. The Wet Installation Method Professional window tinting uses a wet installation technique that creates the conditions for temporary cloudiness. Installation Steps: The installer thoroughly cleans the glass using a pH-balanced cleaning solution. Any dirt, oils, or residue prevents proper adhesion. After cutting the film to precise window dimensions, the installer sprays the glass surface with a soapy water solution. This slip solution allows the film to be positioned correctly before it adheres. The tint film is applied to the wet glass surface. At this point, there’s a significant amount of moisture between the film and the window. Using a squeegee, the installer pushes out as much water as possible, working from the center toward the edges. This removes the majority of the slip solution. Why Moisture Remains: Despite thorough squeegeeing, it’s physically impossible to remove 100% of the water. Microscopic amounts of moisture remain trapped between the film and glass. The film itself is slightly porous at a molecular level. This porosity serves an important purpose: it allows trapped moisture to escape through evaporation during the curing process. The squeegee removes perhaps 90% to 95% of the application solution, but that remaining 5% to 10% creates the hazy appearance you see after installation. The Chemical Bonding Process Window tint doesn’t just stick to glass like a sticker. The adhesive undergoes a chemical curing process. How Adhesive Works: Window film uses pressure-sensitive adhesive (PSA) engineered specifically for glass application. This adhesive requires time to form proper molecular bonds with the glass surface. During installation, the adhesive is activated by the moisture in the slip solution. As moisture evaporates, the adhesive transitions from a semi-liquid state to full bond strength. This curing process is gradual, not instantaneous. The adhesive continues strengthening its bond to the glass over days or weeks. Temperature and sunlight accelerate the curing process by promoting faster evaporation of trapped moisture. Why Window Tint Looks Hazy After Installation The cloudiness you see has specific, understood causes that are part of normal installation. Trapped Moisture Creates Fog Effect The primary cause of haziness is water vapor between the film and glass. The Visual Effect: Light passing through the window encounters the layer of moisture between glass and film. This moisture scatters light, creating the foggy or hazy appearance. Think of it like condensation on a bathroom mirror after a hot shower. The water droplets scatter light, making the mirror appear cloudy even though both the mirror and the water are transparent. The same principle applies to window tint. The glass is clear, the film is clear, but the moisture layer between them creates temporary opacity. Moisture Distribution: Immediately after installation, moisture is distributed relatively evenly across the window surface. This creates a uniform hazy appearance. As evaporation begins, you may see the haziness clear from the edges first (where evaporation occurs fastest) while the center remains cloudy longer. Some windows show a mottled pattern where certain areas clear faster than others. This is normal and related to variations in temperature, sunlight exposure, and film thickness. Small Water Bubbles Are Normal In addition to general haziness, you’ll likely see small bubbles or water pockets under the film. Water Bubbles vs. Air Bubbles: Water bubbles appear as small, irregularly shaped pockets that may shift slightly in position. These are caused by trapped moisture that hasn’t yet evaporated. They’re completely normal and will disappear during curing. Air bubbles are perfectly round, consistent in size, and don’t change position. These indicate improper installation where air was trapped during application. Air bubbles don’t resolve on their own. What’s Normal: Small water bubbles scattered across the window surface, particularly near edges or in the corners, are part of the curing process. These bubbles may seem to multiply or change size during the first few days as moisture redistributes before evaporating. Water bubbles typically range from pinpoint size to approximately 3 to 5 millimeters in diameter. Larger bubbles warrant closer inspection. When to Be Concerned: If bubbles are perfectly round, uniform in size, and arranged in patterns (often following squeegee stroke lines), these may be air bubbles from poor installation. Bubbles larger than a dime (approximately 18 millimeters) that don’t show signs of shrinking after 10 to 14 days should be evaluated by your installer. Bubbles that grow larger over time rather than shrinking indicate adhesive failure or installation problems. Normal Curing Timeline: What to Expect Understanding the typical curing timeline helps you distinguish normal progress

Can PPF Be Removed Without Damaging Factory Paint? Guide

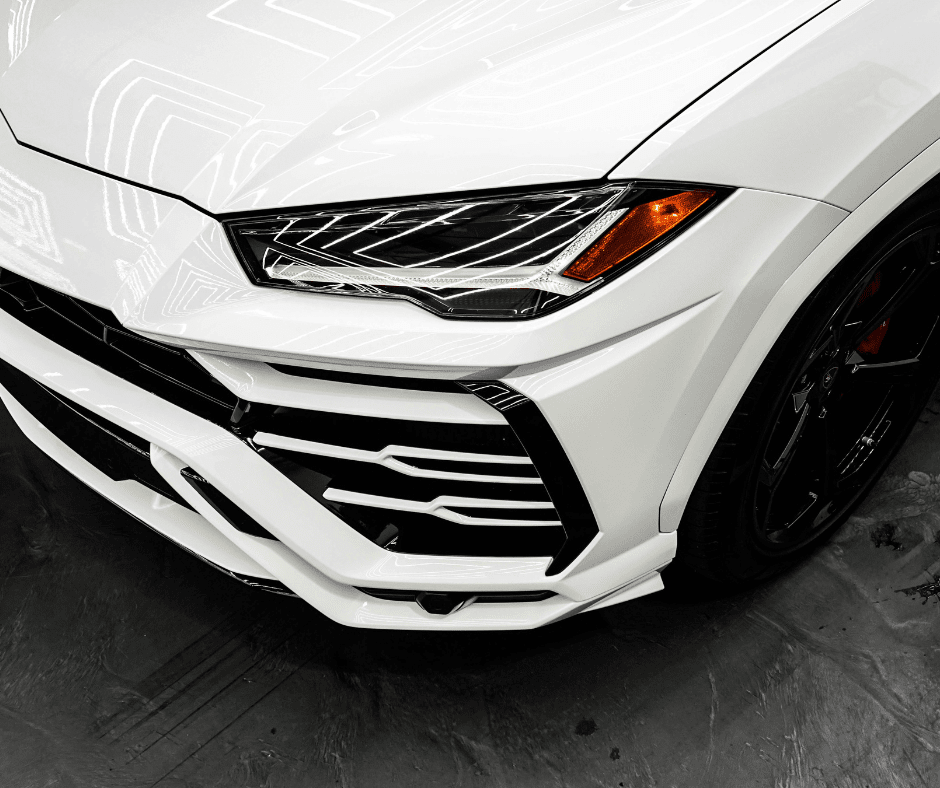

Quick Answer Yes, paint protection film (PPF) can be removed without damaging factory paint when done correctly. The key factors are using controlled heat (heat gun positioned 3 inches away), peeling at a 45-degree angle, and working slowly on small sections. Film age dramatically affects removal difficulty: newer PPF (1 to 5 years old) peels cleanly in large pieces, while older film (5 to 10+ years) becomes brittle and requires significantly more time. Factory paint is much more durable during removal than aftermarket paint jobs, which are vulnerable to peeling. Professional removal eliminates risk but DIY removal is possible with proper technique, patience, and the right tools. Vehicle owners who invested in paint protection film eventually face a decision: when and how to remove it. Whether the film has reached the end of its 5 to 10 year lifespan, shows yellowing or peeling, or you simply want to refresh the protection, removal becomes necessary. The concern is legitimate. You installed PPF to protect your paint. The last thing you want is for the removal process to damage what you worked so hard to preserve. This guide explains exactly how PPF removal works, what determines whether paint stays pristine, and how to avoid the common mistakes that cause damage. Understanding Paint Protection Film Adhesive Systems Before discussing removal, you need to understand how PPF bonds to your vehicle’s paint. How PPF Adheres to Paint Paint protection film uses pressure-sensitive adhesive (PSA) technology. This adhesive bonds to paint through a combination of mechanical and chemical adhesion. The Bonding Process: During installation, the adhesive flows into the microscopic texture and imperfections of your clear coat. This creates mechanical interlocking at a microscopic level. Simultaneously, the adhesive forms weak chemical bonds with the clear coat surface. These bonds are strong enough for permanent adhesion during use but designed to release cleanly during proper removal. The adhesive is specifically formulated to remain removable for years. Unlike permanent adhesives that form irreversible bonds, PPF adhesive maintains its ability to release from the clear coat. What Makes PPF Removable Designed for Removal: Quality PPF brands like XPEL, 3M, and SunTek engineer their adhesives with specific properties: Cohesive strength: The adhesive holds together as a unified layer. When pulled correctly, the entire adhesive layer releases together rather than leaving residue. Release properties: The bond between adhesive and clear coat is weaker than the cohesive strength of the adhesive itself. This ensures the adhesive pulls away from paint cleanly. Temperature activation: Heat softens the adhesive, dramatically reducing its bond strength and making removal easier. Aging characteristics: Quality adhesives are designed to remain removable even after years of UV exposure and weather cycling. Film Age and Adhesive Changes The age of your PPF fundamentally changes the removal experience. Film Aged 1 to 5 Years: The film remains pliable and elastic. Adhesive retains designed release properties. Removal typically proceeds smoothly with large pieces peeling off cleanly. Minimal adhesive residue remains on the paint. Total removal time for a full front end: 2 to 4 hours. Film Aged 5 to 10+ Years: UV exposure causes the urethane film to become brittle and lose elasticity. The film fractures into small pieces during removal instead of peeling in sheets. Adhesive may have bonded more strongly over time, especially if exposed to extreme heat. Significantly more adhesive residue remains after film removal. Total removal time for a full front end: 6 to 12 hours or more. This age-related difference is the single biggest factor determining removal difficulty. Why Factory Paint Rarely Gets Damaged The good news: factory automotive paint is remarkably durable during PPF removal when proper technique is used. Factory Paint Construction Modern factory paint consists of multiple layers applied in carefully controlled conditions: Paint System Layers: E-coat primer: Electrostatically applied corrosion protection bonded directly to metal. This layer is extremely durable. Primer surfacer: Fills imperfections and provides smooth base for color. Base coat: Contains the actual color pigments. Clear coat: 1.5 to 3 mils (40 to 75 microns) thick protective layer. This is what PPF adheres to. Factory Application Process: Paint is applied robotically in dust-free environments at precisely controlled temperatures. Each layer is cured at high temperatures (often 250 to 350°F) to achieve maximum hardness and adhesion. The clear coat is fully cured and bonded to underlying layers before the vehicle leaves the factory. Why Factory Paint Resists Removal Damage Proper Curing: Factory paint has cured for months or years before PPF installation. The layers are fully hardened and bonded. Strong Interlayer Adhesion: The bond between clear coat and base coat is significantly stronger than the bond between PPF adhesive and clear coat. Uniform Thickness: Factory clear coat has consistent thickness across all panels. There are no thin spots vulnerable to damage. Quality Control: Factory paint undergoes testing to ensure proper adhesion and durability before vehicles ship. This is why properly installed and removed PPF virtually never damages factory paint. The paint system is simply too durable. When Paint Damage Can Occur While rare on factory paint, certain conditions increase damage risk during PPF removal. Aftermarket Paint Jobs Repainted vehicles face significantly higher risk during PPF removal. Why Aftermarket Paint Is Vulnerable: Inadequate curing: Body shops often return vehicles within days of painting. Full paint cure can require 30 to 90 days. PPF installed over incompletely cured paint bonds too strongly. Improper surface preparation: Rushed prep work can leave contaminants or inadequate adhesion between paint layers. Thinner clear coat: Some repaints use thinner clear coat than factory specifications to save material costs. Inconsistent application: Hand-applied paint has thickness variations. Thin spots are vulnerable to damage. Lower temperature curing: Most body shops cure paint at lower temperatures than factory ovens, resulting in softer, less durable finish. The result: when PPF is removed from aftermarket paint, there’s genuine risk of pulling paint layers with the film. Extremely Old or Low-Quality Film Bargain PPF products use inferior adhesives that can bond too strongly over time. Problem Films: Generic or off-brand PPF without manufacturer testing.

Can You Apply Ceramic Coating to Plastic Trim, Wheels, or Glass?

Quick Answer Yes, you can apply ceramic coating to plastic trim, wheels, and glass, but each surface requires a specific formulation. Paint-grade ceramic coatings are designed for clear coat and should not be used interchangeably on all surfaces. Trim-specific coatings withstand flexibility and restore faded plastic with 4H hardness and protection up to 24 months. Wheel coatings resist temperatures up to 350°C (662°F) from brake heat. Glass coatings bond differently to non-porous surfaces and prevent wiper chatter that generic coatings cause. Using the correct coating for each surface ensures proper bonding, longevity, and performance. Vehicle owners exploring ceramic coating options often wonder if this protection extends beyond paint. Modern vehicles feature extensive plastic trim, alloy wheels, and glass surfaces that all face environmental damage. The good news is ceramic coating technology isn’t limited to painted panels. The critical factor is understanding that different surfaces have different molecular structures, temperatures, and flexibility requirements. This guide breaks down exactly how ceramic coating works on plastic trim, wheels, and glass, what products to use, and why surface-specific formulations matter. Understanding Ceramic Coating Chemistry for Different Surfaces Ceramic coating consists primarily of silicon dioxide (SiO2), also called silica or quartz. When applied, these nano-particles create a chemical bond with the surface, forming a protective layer typically 2 to 7 microns thick. Why One Coating Doesn’t Fit All Surfaces Molecular Bonding Differences: Paint and clear coat have a porous, slightly flexible surface that allows SiO2 particles to penetrate and bond mechanically and chemically. Glass is non-porous and extremely hard. Coatings designed for paint don’t bond as effectively because glass lacks the microscopic texture that mechanical bonding requires. Plastic trim, especially textured black trim, is semi-flexible and can expand and contract with temperature changes. Rigid paint coatings can crack or delaminate on flexible surfaces. Wheels endure extreme temperatures from brake systems, sometimes exceeding 350°C (662°F) during hard braking. Standard paint coatings aren’t formulated to withstand this heat. Surface-Specific Formulations Paint Coatings: Trim Coatings: Wheel Coatings: Glass Coatings: Ceramic Coating for Plastic Trim Plastic trim includes bumpers, side moldings, mirror housings, door handles, windshield cowls, fender flares, and bed rails on trucks. Why Plastic Trim Needs Protection UV Damage: Prolonged sun exposure breaks down plastic polymers, causing fading and that characteristic gray or chalky appearance. Oxidation: Exposure to oxygen and environmental contaminants creates a dull, lifeless finish. Staining: Road tar, tree sap, and other contaminants bond to unprotected plastic, creating permanent discoloration. Cracking: Dried, damaged plastic becomes brittle and develops surface cracks. Can You Use Paint Coating on Plastic Trim? Technically yes, but it’s not ideal. Paint-grade ceramic coatings will bond to hard, smooth plastic surfaces like smooth bumpers, mirror housings, and glossy trim pieces. Problems with Paint Coatings on Plastic: Too rigid: Paint coatings are formulated for inflexible clear coat. When applied to semi-flexible plastic that expands and contracts with temperature, the coating can crack or peel. Wrong finish: Paint coatings create a high-gloss finish. Most textured black trim looks unnatural with excessive gloss. No color restoration: Paint coatings are transparent and add no pigment. They preserve whatever condition the plastic is in but won’t restore faded trim. Poor penetration on textured surfaces: Paint coatings don’t adequately penetrate the valleys and texture of rougher plastic, leading to uneven protection. Trim-Specific Ceramic Coating Benefits Proper trim coatings deliver specific advantages: Color Restoration: Trim coatings contain mild pigments or oils that restore the deep black color of faded plastic. This isn’t a temporary dressing that washes off but a bonded layer that maintains color. Satin Finish: Instead of high gloss, trim coatings provide a natural satin finish that matches factory appearance. Flexibility: Formulated with slightly more elastic properties to accommodate plastic movement without cracking. UV Protection: Specialized UV inhibitors prevent future fading. Protection typically lasts 18 to 24 months. Hydrophobic Properties: Water and contaminants bead off, making trim easier to clean and preventing staining. Application Process for Plastic Trim Surface Preparation: Application Technique: Apply 2 to 3 drops of trim coating to a microfiber applicator or included sponge. Work in small sections, approximately 12 x 12 inches at a time. For Textured Trim: Apply using a back-and-forth motion, working the coating into all texture and crevices. Do not wipe off on textured surfaces. Apply evenly and leave to cure. The coating will self-level in the texture. For Smooth Trim: Apply a thin, even layer. After 1 to 2 minutes, when the coating begins to flash (appears slightly hazy), buff gently with a clean microfiber towel. This creates a thinner layer that still provides protection but without excessive buildup on smooth surfaces. Curing Time: Avoid moisture exposure for 12 hours minimum. Wait 48 hours before washing the vehicle. Which Trim Pieces to Coat Best Candidates: Avoid Coating: Trim Coating Longevity With proper application and maintenance: Ceramic Coating for Wheels Wheels face some of the harshest conditions on your vehicle: extreme temperatures, corrosive brake dust, road salt, tar, and constant bombardment from road debris. Why Wheels Need Specialized Coating Brake Dust: Comprised of carbon fibers, adhesives, and metal particles that stick aggressively to wheel surfaces. Contains iron particles that embed into pores and cause staining and corrosion. High Temperatures: During heavy braking, wheels can reach 350 to 600°F. Track use or performance driving can push temperatures even higher. Diverse Materials: Modern wheels come in painted finishes, powder coating, polished aluminum, chrome, machined surfaces, and bare metal. Each requires slightly different treatment. Time-Consuming Cleaning: Intricate wheel designs with spokes, vents, and tight spaces make thorough cleaning labor-intensive without protection. Heat Resistance Requirements Standard paint ceramic coatings typically withstand up to 500°F. This is insufficient for wheels. Wheel-Specific Coatings Heat Tolerance: This heat resistance prevents coating breakdown, yellowing, or delamination from brake system heat. Can You Use Paint Coating on Wheels? Professional ceramic coatings formulated for automotive paint will work on wheels for normal street driving where brake temperatures stay moderate. When Paint Coating Works on Wheels: When You Need Wheel-Specific Coating: The consequences of using inadequate coating are yellowing, hazing,

Can Ceramic Coating Be Applied Over Swirl Marks or Scratches?

Quick Answer Technically yes, ceramic coating can be applied over swirl marks and scratches, but you should not do this. Ceramic coating is only 2 to 6 microns thin and completely transparent. It follows the exact contours of your paint surface, which means it amplifies and highlights existing imperfections rather than hiding them. Paint correction must be performed before ceramic coating application to remove swirl marks and scratches. Applying coating over damaged paint permanently seals the flaws in and makes them more visible. Vehicle owners considering ceramic coating often ask whether they need to fix existing paint imperfections first. The marketing surrounding ceramic products sometimes suggests these coatings can fill minor scratches or mask swirl marks. This creates confusion about whether paint correction is truly necessary before coating application. The reality is straightforward but often misunderstood. This guide explains why paint condition matters so much, what happens when you coat over imperfections, and the proper process for achieving the glossy, protected finish ceramic coating promises. Understanding What Ceramic Coating Actually Does Before discussing swirl marks and scratches, you need to understand how ceramic coating actually works. Ceramic Coating Composition Ceramic coating is a liquid polymer primarily composed of silicon dioxide (SiO2), also called silica or quartz. When applied to automotive paint, the formula chemically bonds with the clear coat through a curing process. Physical Properties: The coating creates a semi-permanent protective layer that bonds at the molecular level to your clear coat. This is fundamentally different from wax or sealant, which sit on top of the paint without chemical bonding. What Ceramic Coating Protects Against Ceramic coating provides excellent defense against specific types of damage: Environmental Protection: What It Does NOT Protect: The coating serves as a sacrificial layer, designed to absorb minor damage so your paint doesn’t have to. This protection only works when applied over paint in good condition. The Truth About Coating Over Imperfections Here’s the critical fact many people misunderstand: ceramic coating does not fill, hide, or repair scratches and swirl marks. It makes them more visible. The Magnifying Effect Ceramic coating creates what professionals call the “magnifying effect” or “highlighting effect.” Why This Happens: The coating is completely transparent with no fillers or light-diffusing agents. When you apply it over scratched or swirled paint, the coating simply follows the exact topography of the damaged surface. Because the cured coating has a glass-like, glossy finish, it actually enhances surface reflection, which makes every imperfection stand out more dramatically under light. Think of it like applying a clear gloss varnish over a scratched wooden table. The varnish doesn’t hide the scratches. Instead, the added gloss and reflection make them easier to see. What Happens to Swirl Marks Under Coating Swirl marks are fine circular scratches in the clear coat, typically caused by: When ceramic coating is applied over swirl marks: The nano-particles do seep into the scratches because ceramic coating is liquid during application. This creates the false perception that it “fills” the damage. But when it cures, the coating only forms a smooth layer following the scratch pattern. The swirl marks remain visible in the paint below. Because the coating adds gloss, these marks actually become more apparent under direct light, especially sunlight. The swirls are now sealed under a hard protective layer, making future correction significantly harder. You’ll need to remove or polish through the ceramic coating before you can access the damaged clear coat underneath. Deep Scratches Remain Completely Visible For scratches you can feel with your fingernail: Ceramic coating provides zero visual improvement. These scratches penetrate too deep into the clear coat for any coating to mask. The coating simply bridges over the top of the scratch, leaving a visible groove in the surface. Some people hope the coating will “level” or “fill” deep scratches through surface tension. This doesn’t happen. The coating is too thin (2 to 6 microns) to fill any scratch deep enough to be visible. Why Paint Correction is Essential Before Coating Professional ceramic coating application always includes paint correction as a mandatory preparation step. What Paint Correction Accomplishes Paint correction is a precise process using abrasive polishes and machine polishers to remove a very thin layer of clear coat. The Process: Polishing compounds contain microscopic abrasives that cut away damaged clear coat until the surface of the scratch is level with the surrounding paint. This is called “leveling.” The removed clear coat is redistributed as residue that fills remaining micro-imperfections. With proper technique, this creates an almost perfectly smooth surface. Different polishing compounds and pad combinations handle different severity levels: Paint Thickness Considerations Clear coat thickness limits how much correction is possible. Most factory clear coat measures 40 to 60 microns thick, though luxury vehicles may have 70 to 100 microns. Safe Correction Levels: Professional detailers use paint thickness gauges to measure clear coat depth before correction. This prevents accidentally polishing through to the base coat color layer. The Proper Preparation Sequence Professional ceramic coating application follows a specific preparation sequence: Step Process Purpose Time Required 1. Decontamination Wash Thorough wash with pH-neutral soap Remove loose dirt and grime 30-60 min 2. Clay Bar Treatment Clay medium pulls bonded contaminants Remove embedded particles 45-90 min 3. Paint Thickness Measurement Gauge reading on multiple panels Establish safe correction limits 15-30 min 4. Paint Correction Machine polishing with compounds Remove scratches and swirls 4-12 hours 5. IPA Panel Wipe Isopropyl alcohol removes polish oils Ensure clean bonding surface 15-30 min 6. Ceramic Application Coating applied in small sections Create protective layer 2-6 hours 7. Curing Product cures to full hardness Bond to clear coat 24-48 hours This entire process typically requires 8 to 20 hours of labor, depending on vehicle size and paint condition. What Happens If You Skip Paint Correction Some vehicle owners attempt to save money or time by applying ceramic coating over damaged paint. This creates several problems. Permanent Flaw Preservation Once ceramic coating cures over scratched or swirled paint, those imperfections become essentially permanent to

Does Window Tint Help Keep Your Car Cooler in San Antonio Summers?

Quick Answer Yes, window tint significantly reduces car interior temperature in San Antonio summers. Quality window tint can lower cabin temperature by 8 to 20 degrees Fahrenheit, depending on film type. Ceramic tint blocks up to 85% of infrared heat and 99% of UV rays. With San Antonio summer averages reaching 90 to 96 degrees Fahrenheit, and often exceeding 100 degrees for 22+ days per summer, tinted windows provide measurable cooling benefits that reduce air conditioning strain, protect interiors, and improve driving comfort. San Antonio summers are intense. When temperatures routinely climb into the mid-90s and frequently break 100 degrees, your car becomes a rolling oven within minutes of parking. If you’ve experienced that blast of scorching air when opening your car door after grocery shopping, you know the problem well. The question many San Antonio vehicle owners ask is whether window tinting actually provides meaningful cooling relief, or if it’s just a cosmetic upgrade with minor side benefits. The science and real-world data prove that quality window tint dramatically reduces interior heat. This guide explores exactly how much cooler your car will be, which tint types perform best in San Antonio’s climate, and what the actual temperature differences mean for your daily driving experience. Understanding San Antonio’s Summer Heat Challenge To appreciate window tint’s cooling impact, you need to understand what you’re up against in San Antonio’s summer climate. The Numbers Behind San Antonio Summers San Antonio experiences some of the most intense sustained heat in Texas: Average Summer Temperatures: Extreme Heat Days: Record-Breaking Patterns: What Happens Inside Your Car The greenhouse effect inside vehicles amplifies external temperatures dramatically. Here’s what the science shows: Without Window Tint: Heat Buildup Timeline: Why Cars Get So Hot: This greenhouse effect makes untinted vehicles uncomfortable and potentially dangerous, especially for children, pets, or anyone with heat sensitivity. How Window Tint Reduces Heat: The Science Window tint doesn’t just darken your windows. It actively blocks the specific types of solar energy responsible for heat buildup. The Three Types of Solar Energy Sunlight reaching your car contains three distinct energy types: Visible Light (44% of solar energy): Infrared Radiation (53% of solar energy): Ultraviolet Radiation (3% of solar energy): Quality window tint targets infrared and ultraviolet radiation while allowing varying amounts of visible light through, depending on darkness level. How Different Tint Types Block Heat Not all window films perform equally. The material composition determines heat rejection capabilities. Tint Type Infrared Rejection UV Rejection Heat Reduction Durability Dyed Film 15-25% 40-60% Minimal Fades over time Carbon Film 40-50% 70-80% Moderate (12-15°F) Good (5-7 years) Ceramic Film 50-85% 99% Excellent (15-20°F) Superior (10+ years) Metalized Film 60-70% 90-95% Good Interferes with signals Why Ceramic Performs Best: Ceramic tint uses nano-ceramic particle technology that doesn’t rely on dyes or metals. These microscopic particles specifically target and reflect infrared radiation while maintaining excellent visible light transmission. This means you can have lighter tint shades that still provide exceptional heat rejection. Ceramic films maintain their performance over time because ceramic particles don’t break down from UV exposure like dyes do. Unlike lower-quality dyed films that turn purple and bubble, ceramic tint retains its original appearance and heat-blocking properties for the film’s entire lifespan. The Role of Visible Light Transmission Visible Light Transmission (VLT) percentage indicates how much light passes through tinted windows. Lower VLT means darker tint. Common VLT Levels: Important Clarification: Darker tint doesn’t necessarily mean better heat rejection. A 70% ceramic tint can block more heat than a 5% dyed tint because infrared rejection depends on material technology, not darkness. Texas law requires front side windows to allow more than 25% light transmission, but rear windows and back glass have no restrictions for passenger vehicles. Actual Temperature Reduction: The Data Real-world testing and scientific studies provide concrete numbers on window tint’s cooling performance. Temperature Drop Studies Multiple research projects have measured interior temperature differences: University Studies: Industry Testing: Measured Results by Tint Type: No Tint: Interior reaches 130 to 140 degrees Fahrenheit Dyed Film: Interior reaches 125 to 130 degrees Fahrenheit (5 to 10 degree reduction) Carbon Film: Interior reaches 115 to 120 degrees Fahrenheit (12 to 15 degree reduction) Ceramic Film: Interior reaches 110 to 115 degrees Fahrenheit (15 to 20 degree reduction) Premium Ceramic Film: Interior reaches 105 to 110 degrees Fahrenheit (up to 20+ degree reduction) Heat Rejection Capabilities Beyond absolute temperature numbers, heat rejection percentages indicate how much solar energy is blocked: Total Solar Energy Rejection (TSER): What This Means in San Antonio: On a 100-degree day with your car parked in the sun, ceramic tint blocking 60% of total solar energy means: Surface Temperature Differences Window tint doesn’t just cool the air. It keeps surfaces cooler: Dashboard Temperatures: Steering Wheel: Leather Seats: These surface temperature reductions make immediate practical differences when entering your vehicle. Real-World Impact on San Antonio Driving Temperature numbers and percentages matter, but what do they mean for your daily experience? Morning Commute Scenario Without Tint: Your car sits in the driveway from 7 AM to 5 PM on a typical San Antonio summer day (95 degrees exterior). With Ceramic Tint: Same parking scenario. Time Savings: 5 to 8 minutes less cooling time per entry Daily Benefit: If you enter your car 4 times daily, that’s 20 to 32 minutes saved running AC at maximum Monthly Impact: 10 to 16 hours less maximum AC operation Weekend Errands Running Saturday errands means multiple short stops at different locations. Without Tint: With Ceramic Tint: Long-Term Benefits Beyond immediate comfort, window tint provides ongoing advantages in San Antonio’s climate: Interior Preservation: Health Protection: Energy Efficiency: Resale Value: Choosing the Right Tint for San Antonio With San Antonio’s extreme heat, selecting appropriate window film becomes crucial. Ceramic Tint: The San Antonio Standard For maximum heat rejection in San Antonio’s climate, ceramic tint represents the best value despite higher initial investment. Why Ceramic Wins in Hot Climates: Superior Infrared Rejection: Blocks 50-85% of infrared heat, the primary heat source. In 100-degree San

Can You Wash and Wax a Car With PPF? Proper Care Guidelines

Quick Answer Yes, you can wash and wax a car with paint protection film. Wait 48 to 72 hours after installation before the first wash. Use pH-neutral soap, soft microfiber mitts, and the two-bucket method. Waxing is optional with modern PPF but can add extra gloss and protection. If waxing, use products without kerosene, naphtha (over 5%), dyes, or abrasives. Wash every 2 weeks for daily drivers and wax 1 to 2 times per year if desired. Investing in paint protection film for your vehicle represents a significant commitment to preserving your car’s appearance. Once installed, a natural question arises: how do you maintain it? Can you wash it like regular paint? What about waxing? This guide answers these questions and provides detailed care instructions to help your PPF stay in perfect condition for years. Understanding Paint Protection Film Care Requirements Paint protection film is engineered from thermoplastic urethane, a durable yet flexible material designed to absorb impacts and resist environmental damage. Despite its strength, PPF requires specific care practices that differ slightly from maintaining bare paint. Modern PPF comes with built-in properties that make maintenance easier than ever: Hydrophobic Surface: Quality PPF naturally repels water, causing it to bead up and roll off the surface. This property reduces water spotting and makes washing more effective. Self-Healing Technology: High-end films can repair minor scratches and swirl marks when exposed to heat. This feature maintains the smooth, glossy appearance without manual intervention. Stain Resistance: The film’s smooth surface prevents contaminants like bird droppings, tree sap, and bug splatter from bonding as strongly as they would to bare paint. UV Stability: Premium PPF resists yellowing and degradation from ultraviolet exposure, maintaining optical clarity throughout its lifespan. Can You Wash a Car With Paint Protection Film? Absolutely. Regular washing is not just safe for PPF, it’s essential for maintaining the film’s protective properties and appearance. Dirt, grime, and environmental contaminants that accumulate on the surface can gradually degrade the film if left unattended. When to Start Washing After Installation The most critical consideration is timing your first wash after PPF installation. The adhesive needs adequate time to cure fully before exposing it to water and washing products. Minimum Wait Time: 48 hours for light washing Recommended Wait Time: 72 hours for standard washing Optimal Wait Time: 7 days before intensive cleaning Most professional installers recommend waiting at least 48 hours, though 72 hours provides a safer margin. During this curing period, the film bonds completely to the paint surface, ensuring edges remain sealed and the adhesive reaches maximum strength. How Often Should You Wash PPF? Washing frequency depends on your driving conditions and environment: Daily Drivers: Every 2 weeks minimum Highway Commuters: Every 1 to 2 weeks (more bug and road debris exposure) Garage-Kept Weekend Cars: Once per month or as needed Vehicles in Harsh Climates: Every 1 to 2 weeks (high UV, salt, or industrial fallout) Regular washing prevents contaminant buildup that can etch into the film or create staining. In San Antonio’s climate, the intense sun and occasional dust storms make biweekly washing particularly important for daily drivers. Proper PPF Washing Technique The washing method you use significantly impacts PPF longevity and appearance. Following the right technique prevents accidental damage while effectively cleaning the surface. Required Supplies Item Specification Purpose Car Shampoo pH-neutral, wax-free Gentle cleaning without residue Wash Mitts Soft microfiber, 2 required Prevents scratching, one for wheels Buckets 2 large buckets with grit guards Two-bucket method execution Drying Towels Premium microfiber, waffle weave Water removal without marring Wheel Cleaner pH-neutral, non-acidic Safe for PPF overspray Hose or Pressure Washer Pressure washer: 1,200 to 1,900 PSI Pre-rinse and final rinse The Two-Bucket Method This proven technique minimizes the risk of scratching by keeping your wash mitt clean: Bucket 1 (Wash Bucket): Fill with water and pH-neutral car shampoo according to product instructions. Bucket 2 (Rinse Bucket): Fill with clean water only. Add a grit guard to the bottom if available. Process: This method prevents dirt particles from being reintroduced to the wash solution, which would then scratch the PPF as you clean. Step-by-Step Washing Process 1. Pre-Rinse (5 minutes) Thoroughly rinse the entire vehicle to remove loose dirt, dust, and debris. This step is crucial because it eliminates particles that could scratch during the contact wash. If using a pressure washer, maintain these guidelines: 2. Wheels First (10 minutes) Clean wheels before the body to prevent splashing brake dust and road grime onto clean paint. 3. Body Washing (15 to 20 minutes) Work from top to bottom in sections: Technique Notes: 4. Final Rinse (5 minutes) Remove all soap residue with a thorough rinse: 5. Drying (10 to 15 minutes) Proper drying prevents water spots, especially in San Antonio’s hard water areas: Best Method: Use a premium waffle-weave microfiber drying towel. Pat and glide across surfaces rather than rubbing vigorously. Alternative Method: Use a car blower or leaf blower to remove water without touching the surface. This touchless method is ideal for maximizing PPF longevity. Avoid: Chamois or traditional towels, which can trap particles and create scratches. What to Avoid When Washing PPF Automatic Brush Car Washes: Stiff rotating brushes can lift film edges, create scratches, and gradually damage the surface. The harsh chemicals used in many automatic washes can also degrade PPF properties. Harsh Chemicals: Avoid cleaners containing: Abrasive Tools: Never use: Dirty Mitts: Always keep your wash mitt clean. A single piece of grit can create scratches across an entire panel if dragged through the washing process. Hot Water: Excessively hot water can affect adhesive properties, especially along edges. Use cool to lukewarm water for washing. Can You Wax a Car With Paint Protection Film? Yes, you can apply wax over PPF, but it’s not always necessary. Modern paint protection films, especially high-quality products, already feature hydrophobic top coats that provide many of the benefits traditionally achieved through waxing. Understanding When Waxing Makes Sense Situations Where Waxing Helps: Enhanced Gloss: If you want maximum shine and depth

How Much Paint Protection Film Coverage Do You Really Need? Partial vs Full Front Explained

Quick Answer The right PPF coverage depends on your driving habits and budget. Partial front coverage (typically 18-24 inches of hood and front areas) works well for city drivers, while full front coverage (entire hood, fenders, bumper, mirrors, and lights) is better for highway commuters. Studies show that full front PPF can reduce paint defects by up to 60% over five years and may increase resale value by 15%. Protecting your vehicle’s paint is more than just keeping it looking good. It’s about preserving your investment and avoiding costly repairs down the road. Paint protection film has become the go-to solution for car owners who want serious protection against road damage, but choosing between partial and full front coverage can feel overwhelming. This guide breaks down everything you need to know about PPF coverage options so you can make the right choice for your vehicle and driving conditions. What Is Paint Protection Film and How Does It Work? Paint protection film is a clear, thermoplastic urethane layer that bonds to your vehicle’s painted surfaces. Think of it as invisible armor for your car. Originally developed for military helicopters to protect rotor blades from debris, PPF technology has evolved significantly for automotive use. Modern PPF offers several protective features: Self-Healing Technology: High-quality films can repair minor scratches automatically when exposed to heat from the sun or warm water. The urethane material has memory properties that allow it to return to its original smooth state. Impact Absorption: The film acts as a sacrificial layer, absorbing the force from road debris, rock chips, and minor impacts before they reach your paint. UV Protection: Quality PPF blocks harmful ultraviolet rays that cause paint fading and oxidation over time. Chemical Resistance: The film creates a barrier against acid rain, bird droppings, bug splatter, and tree sap that can etch into bare paint. Hydrophobic Properties: Many modern films repel water and dirt, making your vehicle easier to clean and maintain. The film typically lasts between 5 to 10 years when properly maintained, providing long-term protection that preserves your vehicle’s appearance and resale value. Understanding PPF Coverage Options Partial Front Coverage: Targeted Protection Partial front coverage focuses on the highest-risk areas where damage occurs most frequently. This strategic approach protects vulnerable zones without the investment required for full coverage. What’s Typically Covered: Installation Time: Most partial front installations take between 4 to 8 hours, depending on your vehicle’s complexity and the installer’s experience. This option appeals to drivers who want essential protection at a more accessible price point. The coverage targets areas that statistically receive 80-90% of road debris impacts during normal driving. Full Front Coverage: Comprehensive Shield Full front coverage extends protection across all forward-facing surfaces, creating a complete barrier against everything the road throws at your vehicle. What’s Typically Covered: Installation Time: Expect full front installations to take 1 to 2 days as installers carefully wrap each panel for seamless coverage. Full front coverage eliminates visible seam lines that can occur with partial coverage and provides uniform protection across the entire front section of your vehicle. Partial vs Full Front PPF: Side-by-Side Comparison Factor Partial Front Coverage Full Front Coverage Protection Level Covers high-impact zones (bumper, hood leading edge, fender tips) Complete coverage of all front-facing surfaces Typical Installation Time 4-8 hours 1-2 days Best For City driving, light highway use, budget-conscious buyers Highway commuters, new vehicles, long-term ownership Visible Seam Lines Yes, where film ends on hood and fenders Minimal, cleaner aesthetic Coverage Percentage Protects approximately 30-40% of vulnerable areas Protects 100% of front-end surfaces Durability Period 5-10 years with proper care 5-10 years with proper care Impact on Resale Moderate protection benefit Higher resale value preservation Who Should Choose Partial Front Coverage? Partial coverage makes practical sense for specific driving scenarios and vehicle uses: City and Suburban Drivers: If most of your driving happens at lower speeds on city streets and suburban roads, you face less risk from high-velocity road debris. Partial coverage protects the areas most likely to encounter minor impacts. Budget-Conscious Vehicle Owners: When you want meaningful protection but need to manage costs, partial coverage delivers protection where it matters most without the investment of full coverage. Newer or Certified Pre-Owned Vehicles: If your car already has some miles but you want to prevent further damage to high-impact areas, partial coverage provides targeted protection. Leased Vehicles: Many lessees choose partial coverage to avoid excess wear and tear charges at lease end without committing to full vehicle coverage. Daily Commuters with Short Distances: When your daily drive involves predictable, low-risk routes with minimal highway exposure, partial coverage often provides sufficient protection. The main consideration with partial coverage is the visible transition line where the film ends. This seam becomes more noticeable over time as dirt and wax can accumulate along the edge. Regular cleaning helps minimize this effect. Who Should Choose Full Front Coverage? Full front coverage suits drivers who demand comprehensive protection: Highway Commuters: Frequent highway driving exposes your vehicle to high-velocity debris, gravel from construction zones, and rocks kicked up by trucks. Full front coverage becomes essential insurance against this constant barrage. Performance and Luxury Vehicle Owners: When you’ve invested in a premium vehicle, full front coverage protects your investment and maintains factory-fresh appearance. New Vehicle Buyers: Getting full front PPF installed immediately after purchase means your paint stays perfect from day one. No existing chips need correction before installation. Long-Term Ownership Plans: If you plan to keep your vehicle for 7-10 years or more, full front coverage pays dividends by preventing damage that would otherwise accumulate and reduce resale value. Dark or Special Paint Colors: Darker colors show every imperfection, scratch, and chip more visibly. Special paint finishes like matte, satin, or custom colors are expensive to repair. Full coverage prevents these costly issues. Frequent Road Trip Enthusiasts: Regular long-distance driving through varying road conditions increases your exposure to all types of debris and environmental hazards. Research from the Auto Paint Protection Association indicates that vehicles with full

How to Tell if Your Ceramic Coating is Still Working?

A ceramic coating provides a durable layer of protection for your car’s paint, repelling water, dirt, and contaminants. However, over time, you may start questioning whether your coating is still effective. If you’re unsure about your coating’s condition, professional ceramic coating services in San Antonio can inspect and refresh your vehicle’s protection. The good news is that there are clear signs and tests to determine if your ceramic coating is still working. To help you accurately assess your coating’s condition, this guide will cover: Key Takeaways Signs That Your Ceramic Coating is Still Working 1. Strong Water Beading Effect A properly functioning ceramic coating repels water, causing it to bead up into tight, round droplets rather than spreading across the surface. If you notice: ✅ Small, spherical water beads forming on the surface ✅ Water rolling off easily when the car is rinsed Then your ceramic coating is still active. 2. Efficient Water Sheeting Apart from beading, ceramic coatings promote water sheeting, where water glides off the surface quickly, leaving minimal residue. If after rinsing your car, water clears away in large sheets with little to no standing water, your coating is in good condition. 3. Contaminants Are Easy to Remove One of the main benefits of ceramic coatings is their resistance to dirt, grime, and environmental contaminants. ✅ Dirt, dust, and bird droppings wipe off easily without sticking ✅ Bugs and road grime don’t require excessive scrubbing Your coating is still providing protection. 4. Slick and Smooth Surface When ceramic coatings are fresh, they leave the surface feeling extremely slick. Run your fingers (clean and dry) over the paint after washing. If it still feels smooth and slippery, your coating is likely intact. A rough or tacky feeling may indicate a failing coating. 5. Chemical Resistance to Light Cleaners Ceramic coatings resist chemical breakdown from mild cleaners. A good way to check is to: If any of these indicators are absent or weakening, it’s time to check for signs that your ceramic coating needs maintenance to restore its protective capabilities. Tests to Check if Your Ceramic Coating is Still Working Test Name How to Perform What to Look For Water Bead Test Pour water on the car and observe the droplets. Tight, round beads indicate an active coating. Water Sheeting Test Rinse the car with a hose and watch how the water behaves. Water should slide off quickly, leaving little residue. Hand Feel Test Run clean, dry fingers over the surface. A slick and smooth feel suggests the coating is intact. Dirt Repellency Test Spray a light mist of dust or dirt on the surface and rinse with water. If dirt washes away easily, the coating is still functional. Factors That Affect the Longevity of a Ceramic Coating How to Extend the Life of Your Ceramic Coating Conclusion Knowing if your ceramic coating is still working is simple if you pay attention to key indicators like water beading, sheeting, and surface slickness. Regular maintenance and proper washing techniques can significantly extend the coating’s lifespan. If your coating shows signs of weakening, consider using a ceramic booster spray or reapplying a fresh coat. By keeping your ceramic coating in optimal condition, you ensure your vehicle remains protected from contaminants while maintaining a glossy, hydrophobic finish.

Why Does My Car’s Paint Feel Rough Even After a Wash?

After spending time washing your car, expecting it to feel smooth and glossy, you run your hand over the surface only to find that it still feels rough. This can be frustrating, but you’re not alone. Many car owners experience this issue, which is why professional auto detailing services offer specialized treatments to remove stubborn contaminants that a standard wash can’t eliminate. In this guide, we will explore the common causes of rough paint, how to diagnose the problem, and the best ways to restore that smooth, showroom-like finish to your vehicle. Key Takeaways Common Causes of Rough Car Paint 1. Embedded Contaminants Even though washing removes surface dirt, some microscopic particles bond with the clear coat and won’t come off with soap and water. These include: 2. Oxidation and Fading Over time, UV rays can break down your car’s clear coat, leading to oxidation. Oxidized paint often feels rough and chalky, especially on older or unprotected vehicles. 3. Improper Washing Techniques Using a dirty wash mitt, not rinsing thoroughly, or washing with hard water can lead to contaminants remaining on the surface. In some cases, automatic car washes with abrasive brushes can also leave behind micro-debris. How to Identify What’s Making Your Paint Feel Rough If you’re unsure what’s causing the rough texture, here’s a simple test: Test Type How to Do It What It Reveals Plastic Bag Test Place your hand inside a plastic bag and lightly glide it over the surface. If it feels bumpy, your paint has embedded contaminants. Water Bead Test Spray water on the car and observe how it behaves. If water doesn’t bead up and instead spreads out, the paint may have oxidation or contaminants. Visual Inspection Look at the paint under direct light. Specks of tar, sap, or metal particles may be visible. How to Restore a Smooth Finish Step 1: Wash Properly Step 2: Use a Clay Bar or Clay Mitt Clay barring removes embedded contaminants that a regular wash cannot. Step 3: Chemical Decontamination (Iron Removers & Tar Removers) Step 4: Polish & Protect the Paint Once contaminants are removed, polishing can help restore shine and smoothness. Regular Maintenance for Preventing Paint Contamination Additionally, protecting your vehicle’s interior is just as important, choosing the best floor mats for your vehicle prevents dirt and debris from accumulating inside your car. Conclusion If your car’s paint feels rough even after a thorough wash, it’s likely due to embedded contaminants that require specialized treatment. Clay barring, iron removers, and protective coatings can restore and maintain a smooth finish. By following a proper maintenance routine, you can keep your car’s paint looking and feeling like new for longer.

How to Remove Tree Sap, Bird Droppings, and Bugs Without Damaging Your Coating?

Keeping your car’s exterior clean isn’t just about aesthetics- it’s about protecting your paint and coating from damage. At Alamo Auto Aesthetics’ detailing services in San Antonio, we specialize in safely removing contaminants like tree sap, bird droppings, and bug splatters without harming your ceramic coating, paint protection film (PPF), or wax. Tree sap, bird droppings, and bug splatters are common contaminants that, if left untreated, can cause staining, etching, and deterioration of your vehicle’s protective layers. In this guide, you’ll learn the safest and most effective methods to remove these stubborn residues without harming your ceramic coating, paint protection film (PPF), or wax. Key Takeaways Safest Ways to Remove Bird Droppings Without Damaging Your Coating Bird droppings are highly acidic, often containing uric acid with a pH level between 3 and 4. If left for too long, they can eat through clear coats and coatings. Here’s how to remove them safely: Step 1: Act Fast Step 2: Use a pH-Neutral Cleaner Step 3: Let It Soak Step 4: Wipe Gently Step 5: Apply a Protective Spray How to Remove Tree Sap Without Damaging Your Coating Tree sap is sticky and can bond strongly to your paint and coatings. Over time, it hardens, making removal difficult. Follow these steps to remove sap safely: Step 1: Identify the Sap Type Step 2: Use an Isopropyl Alcohol (IPA) Solution Step 3: Use a Dedicated Tar & Sap Remover Step 4: Use Clay Bar for Residual Sap Step 5: Rinse and Reapply Protection Best Method to Remove Bug Splatters Without Harming Your Coating Bug splatters contain enzymes and proteins that can degrade your coating if left untreated. Here’s the safest way to remove them: Step 1: Pre-Wash the Area Step 2: Apply a Bug Remover Spray Step 3: Let It Dwell Step 4: Wipe With a Microfiber Towel Step 5: Finish With a Sealant or Spray Wax Quick Comparison Table for Removal Methods Contaminant Best Removal Method Recommended Products Bird Droppings pH-neutral cleaner & microfiber towel Quick detailer, ceramic spray Tree Sap IPA solution, tar remover, clay bar 70% IPA, tar & sap remover Bug Splatters Enzyme-based cleaner & microfiber towel Bug remover, citrus cleaner Preventative Measures to Keep Your Car Cleaner for Longer 1. Apply a High-Quality Ceramic Coating or PPF 2. Regularly Wash Your Car 3. Use a Car Cover or Park in the Shade 4. Keep a Quick Detailer & Microfiber Towel in Your Car Understanding why car detailing is important helps you establish a proper maintenance routine that protects your investment. Conclusion Removing tree sap, bird droppings, and bug splatters without damaging your coating is all about using the right products and techniques. By acting quickly, using safe cleaning solutions, and following preventative measures, you can keep your vehicle’s finish in top condition. Regular maintenance and protective coatings further enhance your car’s resilience against these common contaminants. Follow this guide, and you’ll maintain a spotless, well-protected vehicle with ease.